Research

Micro-scale Shape Memory Alloys

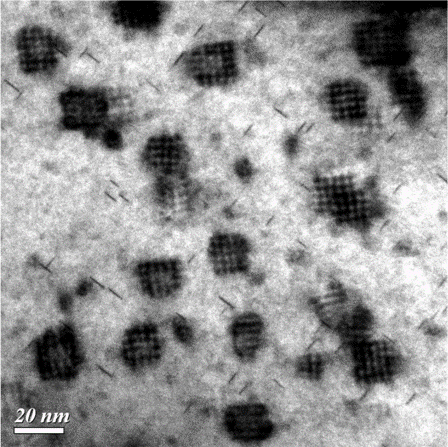

For the applications of shape memory alloys as miniatured actuators or microelectromechanical systems (MEMS), TiNi-based shape memory ribbons were investigated to reveal their functional properties. These ribbons show unique precipitation process, which results in excellent strength, functional stability, shape memory effect, and pseudoelasticity. These studies provide in-deep understandings of the outstanding properties of rapidly solidified TiNi-based shape memory ribbons.

High-entropy Shape Memory Alloys

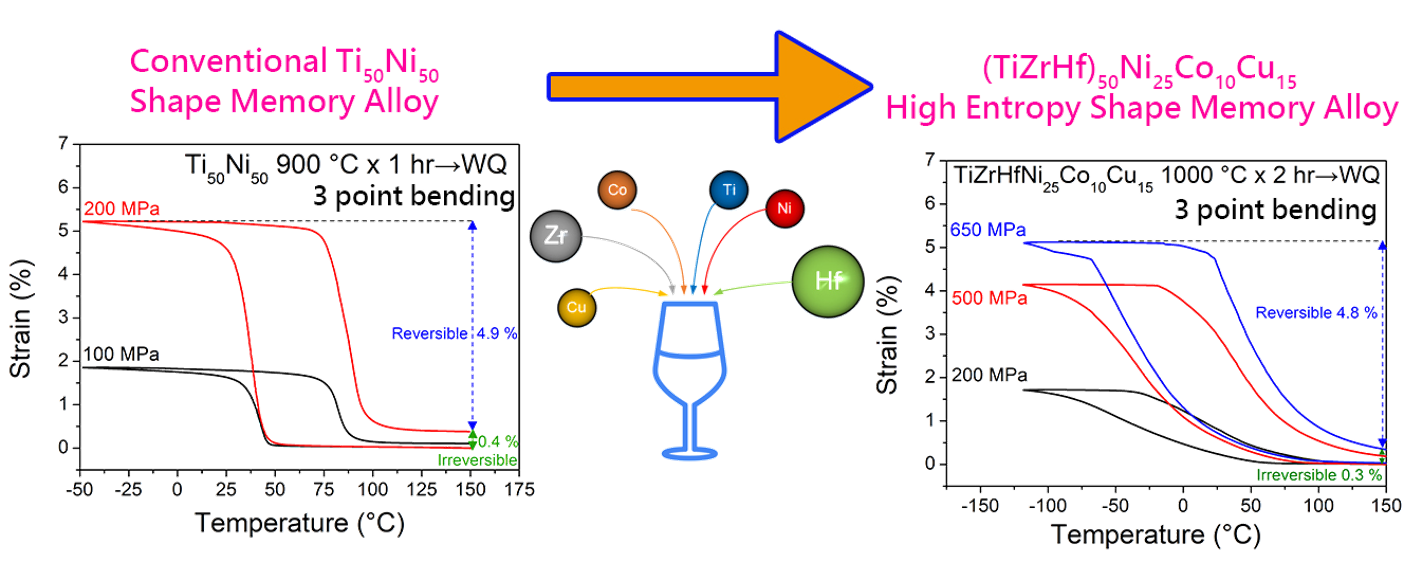

The concept of high-entropy alloy provides a new metallurgical concept to design new shape memory alloys with complex composition. Our group is developing high-entropy shape memory alloys based on the pseudobinary TiNi system. The high-entropy shape memory alloys exhibit higher mechanical strength but retained their excellent functional properties. The concent of high-entropy alloy enables the development and investigation of various novel high-entropy shape memory alloys with unique and fantastic properties.

Elastocaloric Effect

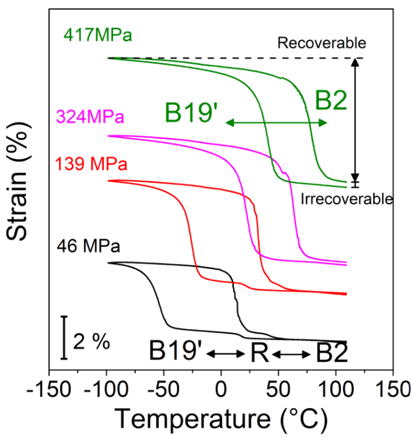

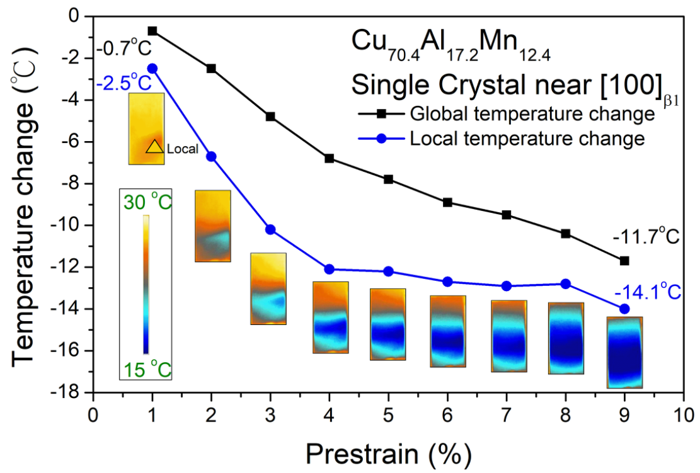

Shape memory alloys are regarded as highly potential materials for serving as solid-state cooling devices. The TiNi-based and Cu-based shape memory alloys are investigated to reveal their elastocaloric effect and operating temperature window. The operating temperature of TiNi-based shape memory alloys can be extended to a lower temperature by introducing intermediate. For Cu-based shape memory alloys, a wide temperature window of about 200 oC can be obtained. These studies promote the understandings and applications of elastocaloric behavior of shape memory alloys.

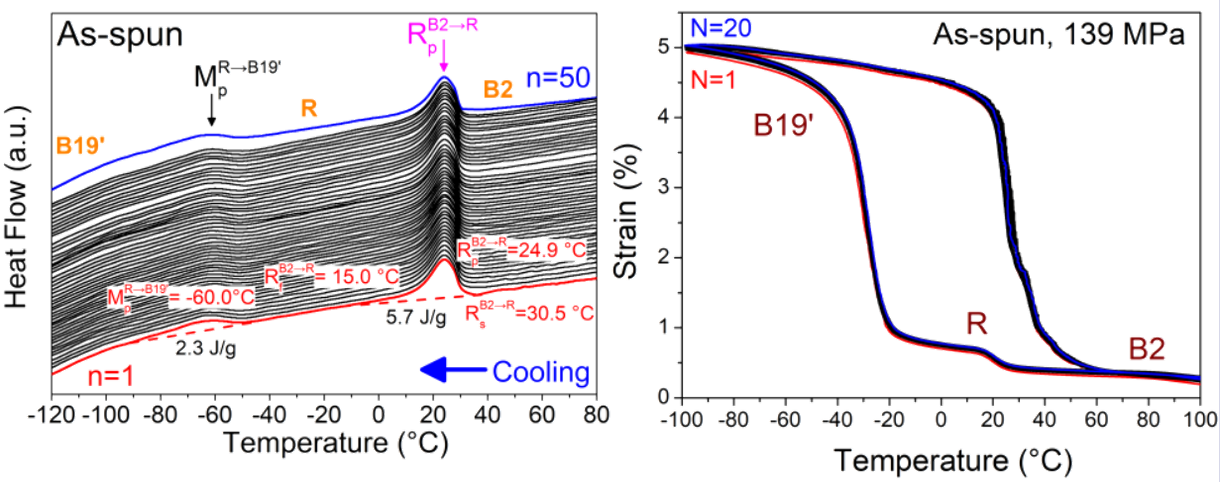

Improved Functional Stability

The functional stability is a critical issue when shape memory alloys are going to be utilized for applications. The functional fatigue of Ti-rich TiNi shape memory alloy is effectively improved by introducing melt-spinning technique. The rapidly solidified Ti-rich TiNi shape memory ribbon exhibits great functional stability and retains considerable transformation strain. This study provides a new way to effectively improve the functional stability of Ti-rich TiNi shape memory alloys.

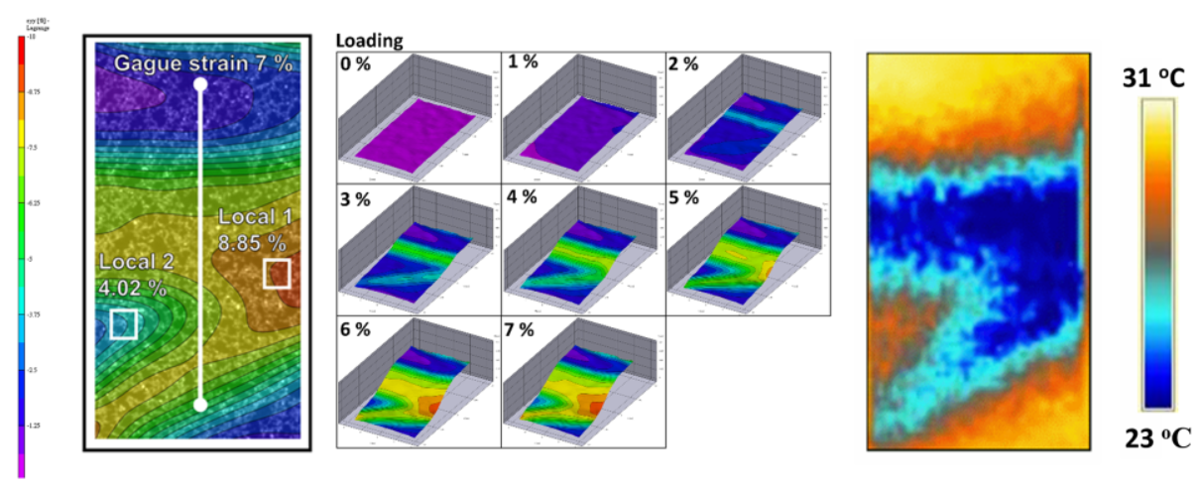

Non-contact Measurements

Non-contact measurements enable recording strain and temperature fields during deformation and phase transformation of shape memory alloys. The distributions of 2D strain field, 3D strain field, and the temperature field can be observed clearly. These methods provide in-deep understandings of the position and the homogeneity of martensitic transformation. Local strains can be detected to evaluate the transformation fraction of shape memory alloys.

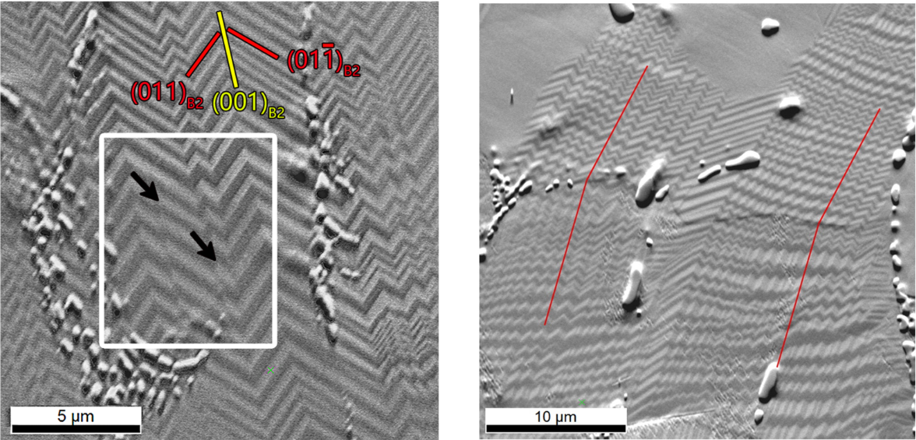

Observation of Martensite Morphologies

A novel method combining the electron backscattering diffraction (EBSD) technique and orientation contrast imaging is developed for identifying the self-accommodation morphologies of R-phase martensite variants. The variants can be observed clearly, and the twinning plane can be easily identified with this method. This method provides the advantages of easy identification of twinning relationships, higher magnification, and simple observations for polycrstalline samples than the conventional method with an optical microscope.